Locus Mining Solutions boosts recovery from declining ores with high-performance, ESG-friendly biosurfactant additives; respected mining professional Gabi Knesel named vice president of new division.

SOLON, Ohio (March 15, 2022) – The clean energy transition requires vast amounts of raw minerals and metals with demand quickly exceeding supply; and today, Locus Fermentation Solutions (Locus FS) has launched a new mining operating division to address this critical issue. Known as Locus Mining Solutions, the division, which will be led by respected mining professional Gabi Knesel, utilizes carbon-neutral biosurfactant additives to boost mineral extraction from low-grade ores.

Locus’ biosurfactant technology shows potential as a top solution for extracting essential minerals, which is currently limited by declining ore grades and growing ESG concerns. The green tech start up is addressing a critical need for sustainable mining techniques that can boost mineral and metal extraction in a more environmentally friendly way. Initial results show up to 138% higher extraction of copper—the most widely used mineral in clean energy technologies.

“The world’s growing reliance on minerals and metals in the transition to a clean energy future is exceeding current extraction capabilities creating an imperative need for sustainable technologies that can reach trapped resources,” said Andrew (Andy) Lefkowitz, co-founder of Locus FS. “Our zero-carbon biosurfactants have an unmatched ability to reach and extract more natural resources. We’re addressing critical environmental and economic concerns to transform the industry, reduce environmental impact and support economic growth in the U.S.”

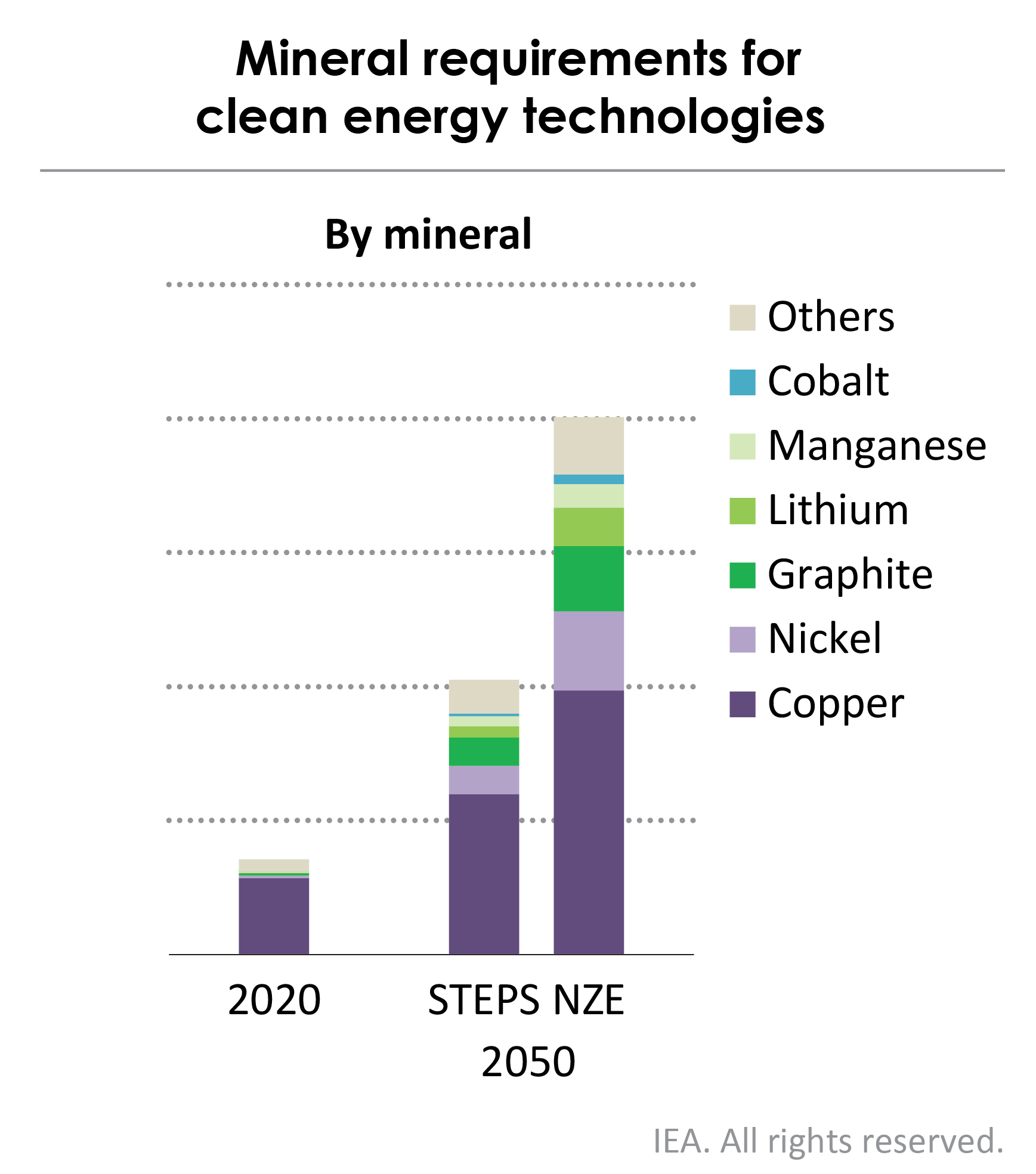

Clean Energy Technologies Require Metals And Minerals That Exceed Current Supply

Net-zero commitments to decarbonize the world’s economies require a move from fossil fuels to renewable energy such as solar or wind power generation, and electric vehicles that rely on batteries and fuel cells. While this transition is less carbon intensive, there are corresponding implications for mining of the minerals and metals needed, namely copper and nickel, along with lithium, cobalt and other strategic and platinum metals. As an example, a wind-powered energy plant requires 9X greater mineral resources than a gas-fired power plant. And an electric vehicle requires 6X the mineral inputs compared to a gas-powered car.

Remaining Ores Are Low Grade And Difficult To Extract

The quality of ores containing these minerals and metals is depleting. These assets are considered “stranded” because it is either economically, technologically or even regulatorily infeasible to extract them with traditional processes. Current extraction methods cannot cost-effectively extract remaining low-grade ores, creating production limitations in existing mining operations. Copper is the cornerstone for all electricity-related technologies, and has the largest growth volume and biggest increase in demand. Yet 80% of all remaining copper is low-grade chalcopyrite ore, which is difficult to extract with traditional methods.

Biosurfactants Meet Supply And Environmental Challenges For Clean Energy Resources

Locus Mining Solutions enables better extraction and higher recovery of metals and minerals using ESG-friendly biosurfactant additives with a near-zero carbon footprint. The 100% renewable biosurfactants can unlock vast amounts of stranded minerals to meet increasing global demand, with performance metrics superior to traditional recovery methods. When tested in copper extraction, the biosurfactant additives resulted in 138% more acid-insoluble copper recovered and 28% better performance than sulfuric acid.

Locus Mining Solutions’ biosurfactant additives are easily incorporated into traditional extraction processes, and require less power, less water and lower transportation costs. This green mining technology generates 40% less carbon dioxide, 70% less sulfur oxides and 70% less nitrogen oxide associated emissions.

The significance of this reduction cannot be overstated, with the U.S. Environmental Protection Agency (EPA) listing metal mining as responsible for 45% of toxic chemical releases (emitted into the air, water, or placed in a landfill) reported to its Toxics Release Inventory (TRI) program in 2020. In comparison, the next highest tally is chemical manufacturing, responsible for 16% of toxic chemical releases in the U.S.

Respected Mining Professional Gabi Knesel Appointed To Lead Biosurfactant Commercialization

Seasoned professional Gabi Knesel, Ph.D., MBA, has been brought on to lead biosurfactant commercialization efforts as vice president of Locus Mining Solutions. Knesel brings with her versatile academia and mining experience, leading global R&D, exploration, operations, sales and business development efforts for Lhoist Group and Nalco/Ecolab’s mining division.

“It is increasingly clear—from my own experience as well as input from thought leaders at the largest global mining companies—that our present and future world requires investment in technologies like biosurfactants that increase recovery while minimizing our environmental footprint. The explosive growth in global consumption of metals and minerals demands it,” said Knesel. “Locus Mining Solutions is well positioned as the best industry partner to achieve a sustainable future for mineral processing and recovery.”

For more information, visit LocusMining.com.

###

ABOUT LOCUS FS

Locus Fermentation Solutions (Locus) is an award-winning, green-tech startup that utilizes the power of microorganisms to create patented, biobased solutions that successfully address global ESG challenges—including climate change, food security, skin conditions, water contamination, the environmental and safety impacts of natural resource extraction, and more. Locus’ cost-effective, near-zero carbon production technology develops solutions tailored to outperform chemicals in a variety of industries. Locus has several subsidiaries including Locus Agricultural Solutions, which helps farmers grow more food and reduce greenhouse emissions; Locus Animal Nutrition, which reduces methane emissions while boosting productivity of livestock; Locus Bio-Energy Solutions, which sustainably increases oil production in declining wells; Locus Mining Solutions, which extracts more minerals and metals needed for the clean energy technologies; and Locus Performance Ingredients, which replaces chemical surfactants in product formulations for consumer product goods. Locus has received 67 industry innovation awards, is actively advancing 11 of the 17 United Nations’ Sustainable Development goals, along with setting net-zero commitments across sectors. With eight offices in five states, the company employs more than 125 people and brings together leading scientists and researchers from all over the world. For more information, visit LocusFS.com.